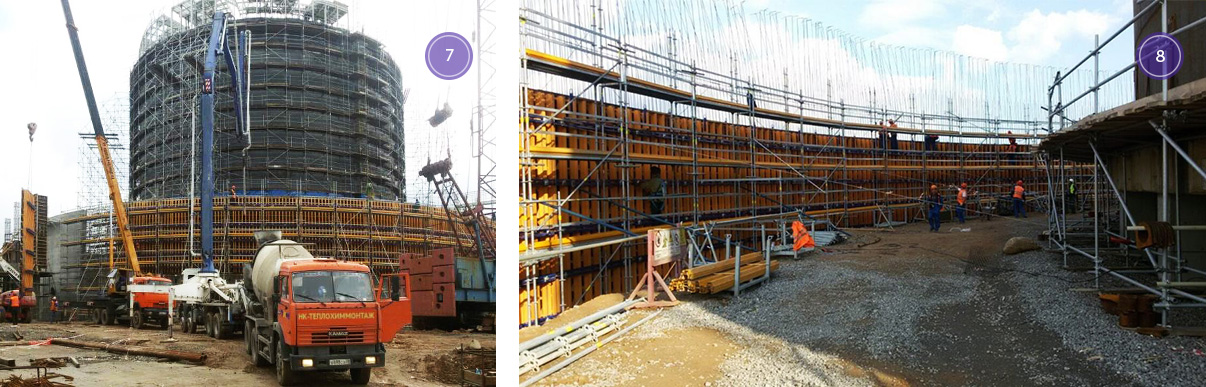

Sliding formwork technology

The main principle of the sliding formwork technology is the process of continuous lifting of the formwork structure vertically, simultaneously with the implementation of general working processes: installation of formwork, reinforcement, concreting and final surface treatment.

The technology of sliding formwork is recognized as the best way for erecting chimneys and silo towers.

Application of sliding formwork

Sliding formwork allows the construction of structures with a constant and variable cross-section, as well as complex objects of conical shape with an inclined axis.

Advantages of sliding formwork

Construction with the use of sliding formwork always takes place in a monolithic manner, that is, without “cold seams”.

The formwork, together with the building shell, rises a few meters a day. Works are conducted 24 hours a day. The lifting process is carried out by continuous steps from 20 to 25 millimeters through clearly defined time intervals. The speed of sliding is 3 to 5 meters per day.

A feature of the use of sliding formwork technology for the construction of chimneys is the possibility of simultaneous lifting of the reinforced concrete trunk and the lining of the pipe.

The use of sliding formwork is especially effective in the construction of high-rise buildings including

- storage of various materials,

- chimneys up to 400 m high,

- cooling towers,

- core rigidity of high-rise buildings,

- reservoirs for water,

- radio and television towers.

An important advantage of erecting such objects with the sliding formwork is a significant increase in the pace of construction, a reduction in labor intensity, cost, and time of work. Unlike prefabricated reinforced concrete structures, joints are excluded in monolithic structures, that contributes to improving the operational characteristics of buildings.

Currently, the technology of sliding formwork is actively used in the construction of various silos and storage tanks for raw materials, and finished products. The wide spread of this method of construction is facilitated by the fact that in the shortest possible time we get durable storage facilities that do not require large financial investments in the process of operation and maintenance.

Features of sliding formwork

From the economic point of view, the most attractive variant is reinforced concrete structures of large capacity.

When carrying out concreting with sliding formwork, special requirements are imposed on the preparation of the mixture. To control the setting time of the mixture, modifiers are used that regulate the time required for strength. The water-cement ratio of concrete varies depending on climatic conditions.

The need to use concrete with guaranteed quality and the continuity of its delivery implies the presence of a mobile concrete plant on the construction site.

Lifting speed of sliding formwork

The lifting speed of the sliding formwork is determined by the cement setting time under specific working conditions. The presence of a certified laboratory and mobile laboratories on job sites allows for the on-line monitoring of incoming materials.