One of the priority directions of development of the holding company “NK-Teplokhimontazh” is the manufacturing of modern furnaces with gas and electric heating.

This is due primarily to the fact that similar equipment currently in use at the machine-building and metallurgical enterprises of the CIS, often does not meet the requirements for safety in the gas sector, does not meet the modern requirements for heating quality, especially in the area of absence of scale formation and cracking.

In addition, existing furnaces lined with heavyweight refractory materials negatively perceive frequent thermal changes, which causes consumers to keep them in working order when there is no load, resulting in increased power consumption.

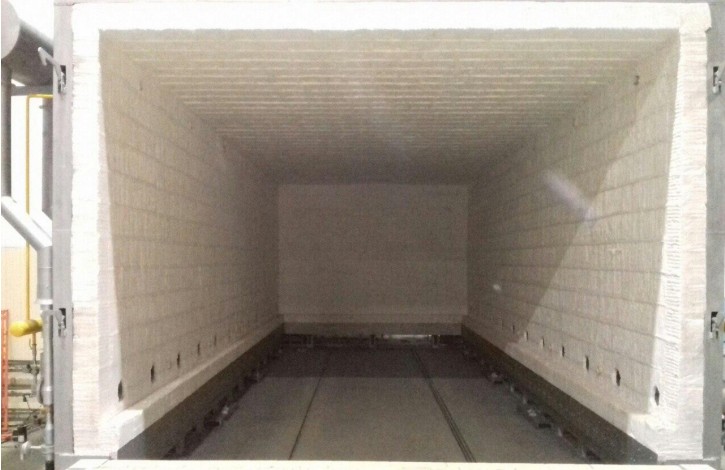

For objects lining a wide range of refractory materials is used.

The holding company NK-Teplokhimontazh has its own production of refractory products: heat-resistant concrete,

light weight refractories, thermal modules.

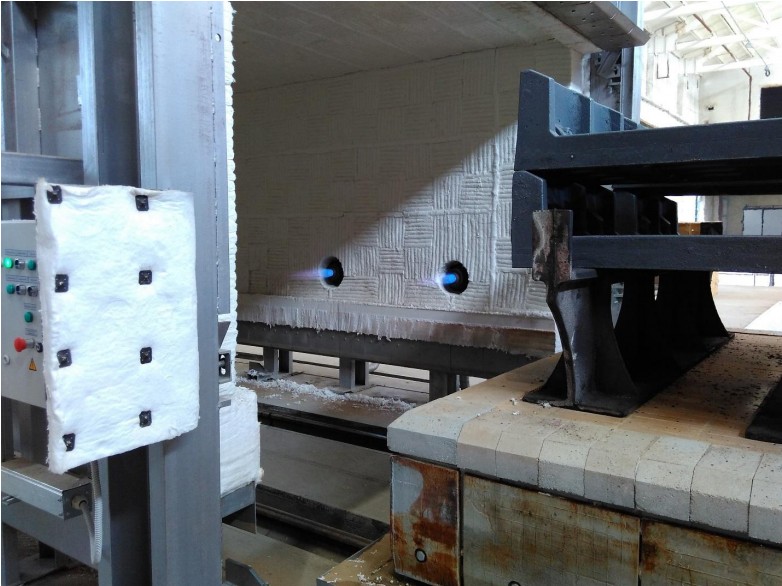

The gas burner equipment uses products of such manufacturers as Kromschroder, NOXMAT, Hauck, WS Warmeprozesstechnik GmbH. In addition, at the moment the holding company develops its own high-speed burners.

The control systems use equipment by SIEMENS, VIPA, Schneider Electric, Phoenix Contact, Weidmuller, ABB, DKS, Thermodat, Oven, etc.

When building a control system, the wishes of the Customer are always taken into account, but the architecture based on the programmable logic controller (PLC) is the priority.

In the whole spectrum of our equipment we offer an automated workstation (AWS).

In the minimum configuration, AWS allows the collection and storage of process data. And in the maximum – a complete management of the technological process with the logging of all events.

The furnaces of the holding company NK-Teplokhimontazh are distinguished by a wide variety of designs and the principle of operation.

Types of furnaces

- Chamber furnaces with a stationary hearth for small and medium billets.

- Chamber furnaces with withdrawable hearth for medium and large billets.

- Pit furnaces for heating billets before bending.

- Furnaces with controlled vector of a torch for obtaining steeply bent taps.

- Pusher furnaces with a rigid hearth and glissazhnye pipes.

- Furnaces with walking beams.

- Ring furnaces.

- Conveyor furnaces for heating sheet blanks.

- Furnaces with an external conveyor for heating the ends of blanks, etc.

By the principle of work we offer

- Direct and indirect heating furnaces.

- Gas and electric furnaces.

- Furnaces with oxidizing environment and controlled level of CO (mainly for the ceramic industry).

There is also experience in working with various modes of accelerated cooling.

NK-Teplokhimontazh performs works on designing, manufacturing and turnkey delivery of new thermal equipment.

The company specialists modernize obsolete operating equipment for thermal, chemical-thermal processing and heating of metals, alloys, machine parts of metallurgical and machine-building enterprises.

The quality of all components and assemblies meets international standards.